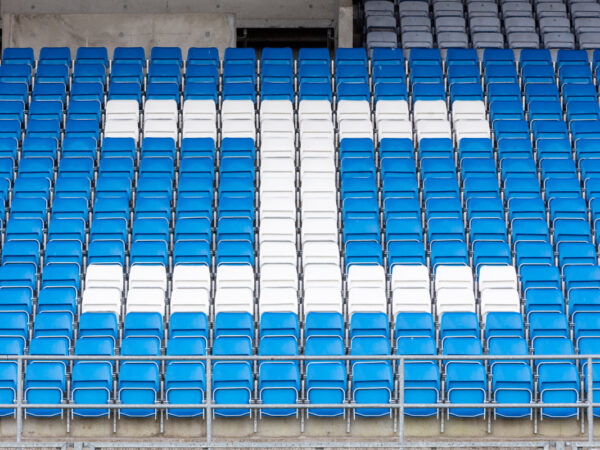

The SYS95 two piece, self tipping, polypropylene seat.

Our most popular general spectator seating solution.

Installation of SYS95 Stadium Seats- These instructions relate to 500mm centre floor fix seats bearing in mind that floor fixed end columns need to be marked separately because the plates are offset.

- Measure the distance between steps where seats are to be installed allow an additional 40mm on each overall measurement for the end column.

- Example 10 seats at 500mm = 5000 plus 40 mm = total 5040, if there is extra space divide by 2 to centralise the seats and that becomes the start point for the first column.

- Example 10 seats at 500mm = 5040mm actual measurement 5200mm surplus = 160mm divide by two = 80mm the first seat should be set 80mm from the step.

- Produce a drilling template by setting several columns on a piece of timber at 500mm centres and mark two holes of the floor plates (opposite corners).

- Lightly mark the holes through the drilling template, when all holes are marked and you are sure all are in the correct place proceed to drill all the holes to the correct depth 70mm deep. You will need to drill 10mm holes and assemble the provided bolts.

- Bolt, 8mm washer and brass expanding anchor, the anchor has a taper thread and you need to screw it on until it just starts to open, too much and you will break them when you try to knock them in, too little and they will not tighten.

- When all holes are drilled and anchors assembled set out the columns.

- Align fixing bolts with drilled holes and hammer in but not all the way so that the column still moves to allow you to clip in the seats.

- Clip in the seats, they clip on to the top pin in every case and should pivot around until they hit the back stop, as you clip in the seats knock the anchor bolts fully in.

- Fit the backs, the end backs use a shorter bolt 6mm x 60mm and the rest of the backs use a 6mm x 90mm bolt, in the case of the end backs place the 6mm washer on to the 6mm x 60mm bolt and pass it through the column from the walkway side then place one by 20mm black spacers over the protruding bolts and then the backrest place another washer over the bolt and screw on the 6mm nyloc nut finger tight, then place a 6mm washer on to a 6mm x 90mm bolt pass it through the backrest place on one by 20mm black spacers then the bolts go through the column then another one by 20mm black spacers then the next back another washer then a nyloc nut.

- When all backs are fitted set the end column in the correct vertical position using a spirit level and then tighten the anchors, once the first column is correctly set and tightened you should tighten all of the backs before tightening the columns because this brings them into the correct vertical position.

- Once you have checked that all columns and backs are tight check all galvanising for spikes or rough edges and remove with either linishing pads or a file.

SYS95 Operation and Maintenance

The SYS95 range of seating as been designed to offer the most robust of stadium seating whilst at the same time giving the minimum of upkeep and maintenance, however the following points should be observed to maximize the longevity and trouble free operation.

a) CLEANING.

The polypropylene seats and backs should be washed down with a soft cloth or sponge using clean water or water with a small amount of domestic washing up liquid added. On no account should chemical or petrol based cleaning solvents be used as these may attack the surface of the plastic. Cleaning with a hosepipe or jet washer is acceptable but care should be taken in the area of the numbered recess in the backrest in order not to dislodge or loosen the self adhesive number.

b) MAINTENANCE.

The only moving parts of the SYS95 are the seat base pivots which will benefit from a spray of propriety oil occasionally , WD40 or such every 3 months. This should be sprayed lightly down each pivot over the pivot pin.

c) VISUAL CHECK AND INSPECTION.

The SYS95 is manufactured to a very high strength specification to withstand the use and abuse that modern stadium seats are subjected to however nothing is completely indestructible and a regular visual check will generally reveal any damage. The seat back rest is the most vulnerable part of the SYS95 and is normally subjected to the most abuse, in the event of damage the stainless steel bolts and nyloc nuts will

need to be undone using two 10mm spanners and the damaged backrest replaced. In the unlikely event that a seat base is damaged it is easier to drill out the four rivets with the seat still in place and then rivet a new seat on rather than try and remove the seat ring from the columns as the SYS95 is designed not to be easily removed by the supporters.

d) CERTIFICATION.

The SYS95 as been tested to and passed BS EN 12727:2000 Test level 4 and also BS4875; (1985) part 1 to level 5. It as also passed ignition source 0 and flame spread tests in accordance with Current regulations.

SYS95 Tip Up Seat Specification

1) MOULDINGS

THE SEAT AND BACK ARE MOULDED FROM TOP GRADE BLOCK COPOLYMER POLYPROPYLENE, THE BASE MATERIAL BEING BOREALIS BC245MO OR EQUIVALENT APPROVED GRADE.

MAXIMUM RESISTANCE TO UV DEGRADATION OF BOTH MATERIAL AND COLOUR IS ACHIEVED BY ADDING THE BEST AVAILABLE GRADES OF ADDITIVE PRIOR TO MOULDING;

- ALL COLOURS ARE MANUFACTURED FROM HEAT STABLE APPROVED PIGMENTS SUITABLE FOR USE WITH POLYPROPYLENE.

- IN ORDER TO AVOID ANY MOLECULAR REACTION WITH BLUE COLOURING NO ALPHA PIGMENTS ARE USED WITH BETA PIGMENTS.

2) STEELWORK

COLUMN

ALL COLUMNS ARE MANUFACTURED TO SUIT INDIVIDUAL SITE REQUIREMENTS COMPRISING BASICALLY AS FOLLOWS

- MAIN UPSTAND; FROM 50MM X 25MM X 1.5MM ERW STEEL TUBE

- SUPPORT STRAP; FROM 50MM X 25MM X 1.5MM ERW STEEL TUBE

- PIVOT AND STOP PINS; FROM 10MM DIA BRIGHT DRAWN STEEL BAR

- MAIN RING STOP PIN; FROM 12MM DIA BR1GHT DRAWN STEEL BAR

SEAT RING

- MAIN SUPPORT FRAME; FROM 25MM X 12MM X 1.5MM ERW STEEL TUBE

- COUNTER BALANCE WEIGHT; FROM 25MM X 8MM MILD STEEL FLAT

- PIVOT TUBES; FROM 20MM X 20MM X 1.5MM ERW STEEL TUBE

ALL STEELWORK IS MIG WELDED, HOT DIPPED GALVANISED TO BS EN ISO 1461:1999 THEN IF REQUIRED FULLY DIP COATED IN BLACK POLYTHENE TO GIVE A SMOOTH CHIP RESISTANT FINISH.

3) NUMBERING

ALL OF OUR SEATS ARE MOULDED WITH A NUMBER RECESS IN THE CENTRE OF THE BACK REST TO ACCOMMODATE A 25MM SQUARE SELF ADHESIVE VINYL NUMBER, OTHER OPTIONS INCLUDE POLYCARBONATE RIVETED COVERS OR RIVETED ALUMINIUM NUMBERS.

4) FIXINGS

SEAT BACKS ARE FITTED USING A2 STAINLESS STEEL BOLTS WASHERS AND NYLOC NUTS. THE SEAT BASE IS SECURED TO THE SUPPORT RING BY MEANS OF FOUR 5MM LARGE FLANGE ALUMINIUM RIVETS.

The SYS18 two piece, self tipping, polypropylene seat.

The SYS18 as been introduced to offer replacement plastics for most of our competitors seats.